KDON-32000/19000 air separation unit ndiyo huru inotsigira public engineering unit ye200,000 t/a ethylene glycol project. Inonyanya kupa hydrogen raw ku pressurized gasification unit, ethylene glycol synthesis unit, sulfur recovery, uye sewage treatment, uye inopa nitrogen ine pressure yakakwira uye yakaderera kumayuniti akasiyana e ethylene glycol project yekubvisa nekusunga, uye inopawo yuniti yemhepo nemidziyo yemagetsi.

A. MAITIRO ETEKNIKI

Midziyo yekuparadzanisa mhepo yeKDON32000/19000 yakagadzirwa uye inogadzirwa neNewdraft, uye inoshandisa nzira yekuyerera kwemaitiro ekuchenesa kwemolecular adsorption yakazara ine low-pressure, air booster turbine expansion mechanism, product oxygen internal compression, low-pressure nitrogen external compression, uye air booster circulation. Shongwe yepasi inoshandisa high-efficiency sieve plate tower, uye shongwe yepamusoro inoshandisa structural packing uye full distillation hydrogen-free argon production process.

Mhepo isina kuchena inosvetwa kubva mugomba, uye guruva nezvimwe tsvina zvemakanika zvinobviswa nefirita yemhepo inozvichenesa. Mhepo mushure mefirita inopinda mucompressor yecentrifugal, uye mushure mekudzvanywa necompressor, inopinda mushongwe yekutonhodza mhepo. Painotonhodza, inogonawo kuchenesa tsvina inonyungudika nyore nyore mumvura. Mhepo mushure mekubva mushongwe yekutonhodza inopinda mumolecular sieve purifier yekuchinja. Carbon dioxide, acetylene uye hunyoro mumhepo zvinonyungudutswa. Molecular sieve purifier inoshandiswa mumhando mbiri dzekuchinja, imwe yacho iri kushanda imwe ichichinja. Kutenderera kwebasa repurifier kunosvika maawa masere, uye purifier imwe chete inoshandurwa kamwe chete maawa mana, uye otomatiki switching inodzorwa nepurogiramu inogona kugadziriswa.

Mhepo mushure mekusvina molecular sieve adsorber yakakamurwa kuita nzizi nhatu: rwizi rumwe runobviswa zvakananga kubva mumolecular sieve adsorber semhepo yemidziyo yekuparadzanisa mhepo, rwizi rumwe runopinda mu low-pressure plate-fin heat exchanger, runotonhodzwa ne reflux yakasvibiswa ammonia neammonia, uye rwobva rwapinda mushongwe yepasi, rwizi rumwe runoenda ku air booster, uye runokamurwa kuita nzizi mbiri mushure mekudzvanywa kwekutanga kwe booster. Rudzi rumwe runobviswa zvakananga uye runoshandiswa sesystem instrument air ne device air mushure mekuderedzwa mukumanikidzwa, uye rumwe rwizi runoramba ruchimanikidzwa mu booster uye runokamurwa kuita nzizi mbiri mushure mekumanikidzwa muchikamu chechipiri. Rudzi rumwe runobviswa uye runotonhodzwa kusvika patembiricha yemukamuri uye runoenda kumagumo e boosting e turbine expander kuti iwedzere kumanikidzwa, uye rwobva rwaburitswa kuburikidza ne high-pressure heat exchanger uye rwopinda mu expander kuti iwedzere uye ishande. Mhepo yakanyorova yakawedzerwa inopinda mu gas-liquid separator, uye mhepo yakaparadzaniswa inopinda mushongwe yepasi. Mhepo yemvura inobviswa kubva mugasi-liquid separator inopinda mushongwe yepasi semvura yemvura inoyerera, uye imwe rwizi inoramba ichimanikidzwa mu booster kusvika padanho rekupedzisira rekumanikidzwa, uye yozotonhodzwa kusvika patembiricha yemukamuri ne cooler yopinda mu high-pressure plate-fin heat exchanger kuti ishandurwe ne liquid oxygen uye reflux yakasviba nitrogen. Chikamu ichi chemhepo ine pressure inonyungudika. Mushure mekunge mhepo ine pressure yabviswa pasi pe heat exchanger, inopinda mushongwe yepasi mushure mekudhonzwa. Mushure mekunge mhepo yatanga kunyungudika mushongwe yepasi, mhepo ine oxygen-rich liquid air, pure liquid nitrogen uye high-purity ammonia zvinowanikwa. Mhepo ine oxygen-rich liquid air uye pure liquid nitrogen zvinotonhodzwa zvakanyanya mu cooler uye zvinodhonzwa mushongwe yepamusoro kuti zviwedzere kunyungudika. Okisijeni yemvura inowanikwa pasi peshongwe yepamusoro inodzvinyirirwa ne liquid oxygen pombi uye yobva yapinda mu high-pressure plate-fin heat exchanger kuti idzokezve, uye yobva yapinda mu oxygen pipeline network. Liquid nitrogen inowanikwa pamusoro peshongwe yepasi inobviswa yopinda mu liquid ammonia storage tank. Ammonia ine purity yakakwira inowanikwa pamusoro peshongwe yepasi inodziiswazve nechinhu chinochinja kupisa chine pressure yakaderera uye inopinda munetwork yepipeline yeammonia. Nitrogen ine pressure yakaderera inowanikwa kubva kumusoro kweshongwe yepamusoro inodziiswazve nechinhu chinochinja kupisa chine pressure yakaderera uye yobva yabuda mubhokisi rinotonhora, yobva yadzvanywa kusvika ku0.45MPa nenitrogen compressor yopinda munetwork yepipeline yeammonia. Huwandu hwakati hweargon fraction hunotorwa kubva pakati peshongwe yepamusoro uye hunotumirwa kushongwe isina crude xenon. Chikamu chexenon chinonyungudutswa mushongwe isina crude argon kuti chiwane crude liquid argon, iyo inozotumirwa pakati peshongwe isina crude argon. Mushure mekunyungudutswa mushongwe isina crude argon, xenon inonyungudutswa inowanikwa pasi peshongwe. Gasi reammonia rakasviba rinoburitswa kubva pamusoro peshongwe yepamusoro, uye mushure mekudziiswazve nechinhu chinotonhorera, chinochinja-chinja plate-fin yemhepo ine simba shoma uye chinochinja-chinja plate-fin yemhepo ine simba guru uye chinobuda mubhokisi rinotonhora, rinokamurwa kuita zvikamu zviviri: chikamu chimwe chinopinda mu steam heater ye molecular sieve purification system se molecular sieve regeneration gas, uye gasi renitrogen rakasviba rasara rinoenda ku water cooling tower. Kana liquid oxygen backup system ichida kutanga, liquid oxygen iri mu liquid oxygen storage tank inoshandurwa kuita liquid oxygen vaporizer kuburikidza ne regulating valve, uye yobva yapinda mu oxygen pipeline network mushure mekuwana low-pressure oxygen; kana liquid nitrogen backup system ichida kutanga, liquid ammonia iri mu liquid nitrogen storage tank inoshandurwa kuita liquid oxygen vaporizer kuburikidza ne regulating valve, uye yobva yadzvanywa ne ammonia compressor kuti iwane high-pressure nitrogen uye low-pressure ammonia, uye yobva yapinda mu nitrogen pipeline network.

B. SYSTEM YEKUTONGA

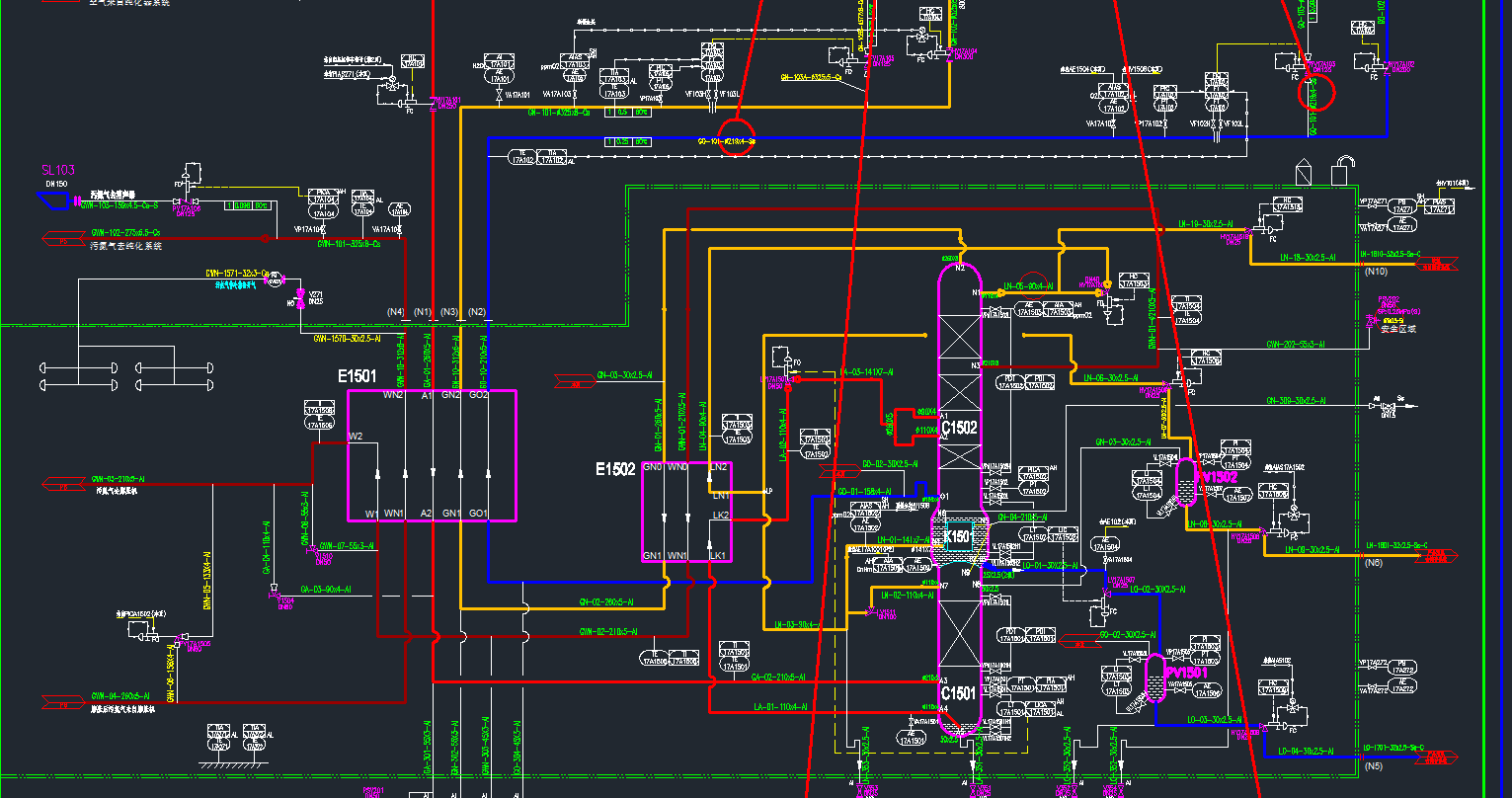

Zvichienderana nehukuru uye hunhu hwemashandiro emidziyo yekuparadzanisa mhepo, sisitimu yekudzora yakagoverwa yeDCS inoshandiswa, pamwe chete nesarudzo yemasisitimu eDCS epamusoro-soro pasi rose, mavharuvhu ekudzora online analyzers nezvimwe zvikamu zvekuyera nekudzora. Pamusoro pekukwanisa kupedzisa kudzora kwechikamu chekuparadzanisa mhepo, inogona zvakare kuisa mavharuvhu ese ekudzora munzvimbo yakachengeteka kana chikamu chikadzimwa mutsaona, uye mapombi anoenderana anopinda mumamiriro ekuchengetedza ekubatanidza kuchengetedza kuti ive nechokwadi chekuti chikamu chekuparadzanisa mhepo chakachengeteka. Mayuniti makuru ecompressor eturbine anoshandisa masisitimu ekudzora eITCC (turbine compressor unit integrated control systems) kupedzisa kudzora kwerwendo rweyuniti kwakanyanya kumhanya, kudzora kwekukurumidzira uye mabasa ekudzivirira kukwira kwemvura, uye inogona kutumira masaini kusystem yekudzora yeDCS nenzira yekubatanidza waya dzakasimba uye kutaurirana.

C. Nzvimbo huru dzekutarisa dzechikamu chekuparadzanisa mhepo

Kuongororwa kwekuchena kweokisijeni yechigadzirwa negasi renitrogen zvichisiya kupisa kwakaderera, kuongorora kuchena kwemhepo yemvura yetower shongwe, kuongorora nitrogen yemvura yakachena yetower shongwe, kuongorora kuchena kwegasi richisiya shongwe yepamusoro, kuongorora kuchena kwegasi richiisa mu subcooler, kuongorora kuchena kweokisijeni yemvura mutower shongwe yepamusoro, tembiricha mushure me crude condenser reflux liquid air constant flow valve, pressure uye liquid level chiratidzo che distillation tower gas-liquid separator, chiratidzo chetembiricha chegasi renitrogen rakasviba richisiya kupisa kwakakwira, kuongorora kuchena kwemhepo ichiisa mu exchanger yekupisa yakaderera, tembiricha yemhepo ichisiya kupisa kwakakwira, musiyano wetembiricha netembiricha yeammonia yakasviba ichisiya kupisa, kuongorora gasi pachiteshi chekuburitsa xenon fraction tower: zvese izvi ndezvekuunganidza data panguva yekutanga uye kushanda kwakajairika, izvo zvinobatsira kugadzirisa mamiriro ekushanda kweyuniti yekuparadzanisa mhepo uye kuona mashandiro akajairika emidziyo yekuparadzanisa mhepo. Kuongororwa kwehuwandu hwe nitrous oxide ne acetylene mukutonhodza kukuru, uye kuongororwa kwehuwandu hwehunyoro mumhepo inosimudzira: kuitira kudzivirira mhepo ine hunyoro kuti isapinde mu distillation system, zvichikonzera kuomarara uye kuvharika kwe heat exchanger channel, zvichikanganisa nzvimbo ye heat exchanger uye kushanda zvakanaka, acetylene inoputika mushure mekunge kuungana mukutonhodza kukuru kwapfuura kukosha kwakati. Liquid oxygen pump shaft seal gas flow, pressure analysis, liquid oxygen pump bearing heater temperature, labyrinth seal gas temperature, liquid air temperature mushure mekuwedzerwa, expander seal gas pressure, flow, differential pressure indication, lubricating oil pressure, oil tank level uye oil cooler rear temperature, turbine expander expansion end, booster end oil inlet flow, bearing temperature, vibration indication: zvese izvi kuti zvive nechokwadi chekuti turbine expander ne liquid oxygen pump zvinoshanda zvakanaka, uye pakupedzisira kuve nechokwadi chekuti air fractionation inoshanda zvakanaka.

Kupisa kweMolecular sieve kumanikidzwa kukuru, kuongorora kuyerera, tembiricha yekupinda nekubuda kweMolecular sieve (nitrogen yakasviba), chiratidzo chekumanikidzwa, tembiricha yekudzoka kweMolecular sieve gas uye kuyerera, chiratidzo chekuramba kucheneswa kwesystem, chiratidzo chekusiyana kwepressure yekunze, tembiricha yekupinda nemhepo, chiratidzo chekumanikidzwa, alarm yekuongorora H20, alarm yekupisa yekunze, alarm yekunze, CO2, tower yekunze, uye chiratidzo chekuyerera kwemhepo: kuona kuti shanduko inoshanda zvakanaka yesystem ye adsorption yeMolecular sieve uye kuona kuti CO2 neH20 zviri mumhepo inopinda mubhokisi rinotonhora zviri padanho rakaderera. Chiratidzo chekumanikidzwa kwemhepo: kuona kuti mweya wemudziyo wekuparadzanisa mhepo nemhepo inopihwa kune network yemapaipi inosvika 0.6MPa (G) kuona kuti kugadzirwa kwakajairika.

D. Hunhu hwechikamu chekuparadzanisa mhepo

1. Hunhu hwemaitiro

Nekuda kwekumanikidzwa kwakanyanya kweokisijeni kweprojekti ye ethylene glycol, michina yekuparadzanisa mhepo yeKDON32000/19000 inoshandisa mhepo inosimudzira mhepo, kumanikidzwa kwemukati meokisijeni yemvura uye nzira yekumanikidza yekunze yeammonia, kureva kuti, air booster + liquid oxygen pump + booster turbine expander inosanganiswa nekurongeka kwakanaka kwe heat exchanger system kutsiva external pressure process oxygen compressor. Njodzi dzekuchengetedza dzinokonzerwa nekushandiswa kwe oxygen compressors mu external compression process dzinodzikira. Panguva imwe chete, huwandu hwakawanda hwe liquid oxygen inoburitswa nekutonhodza kukuru hunogona kuita kuti mukana wekuunganidzwa kwehydrocarbon mu main cooling liquid oxygen unoderedzwa kuitira kuti michina yekuparadzanisa mhepo ishande zvakachengeteka. Internal compression process ine mari shoma yekudyara uye ine gadziriso yakanaka.

2. Hunhu hwemidziyo yekuparadzanisa mhepo

Sefa yemhepo inozvichenesa pachayo ine sisitimu yekudzora otomatiki, iyo inogona kudzoreredza otomatiki nguva uye inogona kugadzirisa purogiramu zvichienderana nehukuru hwe resistance. Sisitimu yekutonhodza inotanga ne tower yekurongedza inoshanda zvakanyanya uye isingadziviriri zvakanyanya, uye mupi we liquid anoshandisa mupi we liquid mutsva, anoshanda uye ane hunyanzvi, uyo kwete chete unovimbisa kubatana kwakazara pakati pemvura nemhepo, asiwo unovimbisa kushanda kwe heat exchange. Wire mesh demister yakaiswa pamusoro kuti ive nechokwadi chekuti mhepo inobuda mu tower yekutonhodza haitakure mvura. Sisitimu ye molecular sieve adsorption inoshandisa cycle refu uye double-layer bed cleansing. Sisitimu ye switching inoshandisa tekinoroji ye switching isina impact, uye steam heater yakakosha inoshandiswa kudzivirira heating steam kuti isadonhe kuenda kudivi re nitrogen yakasviba panguva ye regeneration stage.

Maitiro ese edhisiki yedhisiki yekushandisa distillation tower anoshandisa ASPEN neHYSYS software simulation calculation yepamusoro-soro yepasi rose. Shongwe yepasi inoshandisa sieve plate tower inoshanda zvakanyanya uye shongwe yepamusoro inoshandisa shongwe yekurongedza yenguva dzose kuti ive nechokwadi chekuti mudziyo unoburitswa nekukurumidza uye kuderedza kushandiswa kwesimba.

E. Kukurukurirana pamusoro penzira yekuburutsa nekurodha mota dzine mhepo inotonhodza

1. Mamiriro ezvinhu anofanira kuzadzikiswa usati watanga kupatsanura mhepo:

Usati watanga, ronga uye nyora hurongwa hwekutanga, kusanganisira maitiro ekutanga uye kugadzirisa tsaona dzenjodzi, nezvimwewo. Mabasa ese panguva yekutanga anofanira kuitwa panzvimbo yacho.

Kuchenesa, kusukira uye kuyedza mashandiro esystem yemafuta ekuzora kwapera. Usati watanga pombi yemafuta ekuzora, gasi rekuvharira rinofanira kuwedzerwa kudzivirira kubuda kwemafuta. Kutanga, kusvina kwetangi remafuta ekuzora kunofanira kuitwa. Kana pasvika mwero wakati wekuchenesa, pombi yemafuta yakabatana kuti isvine nekusefa, asi bepa rekusefa rinowedzerwa usati wapinda mucompressor neturbine uye rinogara richitsiviwa kuti mafuta apinde mumidziyo acheneswe. Kusukira nekuiswa kwesystem yemvura inotenderera, system yekuchenesa mvura, uye system yekudhonza mhepo zvinopedzwa. Usati waisa, pombi yakapfuma neokisijeni yekuparadzanisa mhepo inofanira kubviswa mafuta, kubikwa muhari, uye kupiswa, uye yozozadzwa negasi rekuvharira. Mapaipi, michina, magetsi, uye zvishandiso (kunze kwemidziyo yekuongorora nemidziyo yekuyera) zvemidziyo yekuparadzanisa mhepo zvakaiswa uye zvakagadziriswa kuti zvikwanise.

Pombi dzese dzemvura dzinoshanda nemagetsi, pombi dzeokisijeni yemvura, macompressor emhepo, ma booster, ma turbine expanders, nezvimwewo zvine zvinodiwa kuti dzitange kushanda, uye dzimwe dzinofanira kuyedzwa pamuchina mumwe chete kutanga.

Sisitimu yekuchinja masipe emolecular ine mamiriro ekutanga, uye chirongwa chekuchinja masipe emolecular chakasimbiswa kuti chinokwanisa kushanda zvakanaka. Kupisa nekucheneswa kwepombi yemhepo ine simba rakawanda kwapera. Sisitimu yemhepo yemidziyo yakamira yakashandiswa, ichichengetedza kumanikidzwa kwemhepo yemidziyo pamusoro pe0.6MPa(G).

2. Kubvisa mapaipi emhepo anoparadzanisa mayuniti

Tanga sisitimu yemafuta ekuzora uye sisitimu yegesi yekuvharira yeturbine yesteam, compressor yemhepo uye pombi yemvura inotonhorera. Usati watanga compressor yemhepo, vhura vharuvhu yemhepo yecompressor yemhepo wovhara nzvimbo inopinzwa mweya yeshongwe yekutonhodza mweya neplate isina chidzitiro. Mushure mekunge pombi yekubuditsa mweya inokwesha mweya yacheneswa, kumanikidzwa kwekubuda kwemhepo kunosvika pakumanikidzwa kwekubuda kwemhepo kwakayerwa uye chinangwa chekuchenesa pombi chave chakakodzera, batanidza pombi yekubuditsa mweya inotonhodza tower, tanga system yekutonhodza mweya isati yacheneswa (usati wachenesa, kurongedza shongwe yekutonhodza mweya hakufanirwe kuzadzwa; flange yekubuditsa mweya inokwesha molecular sieve adsorber yacheneswa), mirira kusvika chinangwa chave chakakodzera, tanga system yekubuditsa molecular sieve (usati wachenesa, molecular sieve adsorber adsorbent haifanirwe kuzadzwa; flange yekubuditsa mweya inokwesha bhokisi remhepo inofanira kucheneswa), misa compressor yemhepo kusvika chinangwa chave chakakodzera, zadza kurongedza shongwe yekutonhodza mweya uye molecular sieve adsorber adsorbent, uye tangazve firita, turbine yemhepo, air compressor, air precooling system, molecular sieve adsorption system mushure mekuzadza, kwemavhiki maviri ekushanda kwakajairika mushure mekuvandudzwa, kutonhora, kuwedzera kwepressure, adsorption, uye kudzikiswa kwepressure. Mushure menguva yekupisa, mapombi emhepo esystem mushure me molecular sieve adsorber nemapombi emukati eshongwe yekupatsanurwa anogona kuputirwa. Izvi zvinosanganisira ma "heat exchangers" ane simba guru, ma "heat exchangers" ane simba shoma, ma "air boosters", ma "turbine expanders", uye midziyo ye "tower" inoshandiswa pakuparadzanisa mhepo. Nyatsotarisa kudzora kuyerera kwemhepo inopinda mu "molecular sieve cleansing system" kudzivirira kuramba kwakanyanya kwe "molecular sieve" kunokuvadza "bed layer". Usati waputitsa "fractionation tower", mapaipi ese emhepo anopinda mu "fractionation tower cold box" anofanira kunge aine ma "filters" enguva pfupi kudzivirira guruva, welding slag nezvimwe tsvina kuti zvisapinde mu "heat exchanger" uye kukanganisa "heat exchange effect". Tanga "lubricating oil" ne "sealing gas system" usati waputitsa "turbine expander" ne "liquid oxygen pump". Ma "gas sealing points" ese e "air separation tool" e "air separation", kusanganisira "nozzle" ye "turbine expander", anofanira kuvharwa.

3. Kutonhodza kusina chinhu uye kugadzwa kwekupedzisira kwechikamu chekuparadzanisa mhepo

Mapaipi ese ari kunze kwebhokisi rinotonhorera anobviswa, uye mapaipi ese nemidziyo iri mubhokisi rinotonhorera zvinodziiswa nekubviswa kuti zvienderane nemamiriro ekutonhorera uye kugadzirira bvunzo yekutonhorera isina chinhu.

Kana kutonhora kweshongwe yekudiridza kwatanga, mweya unoburitswa necompressor yemhepo haugone kupinda mushongwe yekudiridza zvachose. Mhepo yakawandisa inodzvinyirirwa inoburitswa mumhepo kuburikidza nevharuvhu yemhepo, nokudaro ichichengetedza kumanikidzwa kwekubuditsa kwecompressor yemhepo kusina kuchinja. Sezvo tembiricha yechikamu chimwe nechimwe cheshongwe yekudiridza ichidzikira zvishoma nezvishoma, huwandu hwemhepo inofemerwa hunowedzera zvishoma nezvishoma. Panguva ino, chikamu chegasi re reflux mushongwe yekudiridza chinotumirwa kushongwe yekutonhodza yemvura. Maitiro ekutonhodza anofanira kuitwa zvishoma nezvishoma uye zvakaenzana, neavhareji yekutonhodza ye1 ~ 2℃/h kuve nechokwadi chekupisa kwakafanana kwechikamu chimwe nechimwe. Munguva yekutonhodza, kugona kwekutonhodza kwegasi rekuwedzera kunofanira kuchengetwa pakakwirira. Kana mhepo iri kumucheto wekutonhora kweheat exchanger huru iri pedyo nekupisa kwe liquefaction, danho rekutonhodza rinopera.

Danho rekutonhodza rebhokisi rinotonhora rinochengetwa kwenguva yakati, uye kudonha kwakasiyana-siyana nezvimwe zvikamu zvisina kupera zvinoongororwa uye kugadziriswa. Wobva wamisa muchina nhanho nhanho, tanga kuisa jecha remaparera mubhokisi rinotonhora, tanga michina yekuparadzanisa mhepo nhanho nhanho mushure mekurodha, wobva wapindazve mudanho rekutonhodza. Cherechedza kuti kana michina yekuparadzanisa mhepo yatanga, gasi rekugadzirisa remusefa remamorekuru rinoshandisa mhepo yakacheneswa nesipo yemorekuru. Kana michina yekuparadzanisa mhepo yatanga uye paine gasi rekugadzirisa rakakwana, nzira yekuyerera kweammonia yakasviba inoshandiswa. Munguva yekutonhodza, tembiricha mubhokisi rinotonhora inoderera zvishoma nezvishoma. Sisitimu yekuzadza ammonia mubhokisi rinotonhora inofanira kuvhurwa nenguva kudzivirira kumanikidzwa kwakaipa mubhokisi rinotonhora. Zvadaro michina iri mubhokisi rinotonhora inotonhodzwa zvakanyanya, mhepo inotanga kunyungudika, mvura inotanga kuoneka mushongwe yepasi, uye maitiro ekunyungudutsa eshongwe dzepamusoro nedzepasi anotanga kusimbiswa. Wobva wagadzirisa zvishoma nezvishoma mavharuvhu rimwe nerimwe kuti kupatsanura mhepo kushande zvakanaka.

Kana muchida kuziva rumwe ruzivo, ndapota taurai nesu pachena:

Bata: Lyan.Ji

Nhare: 008618069835230

Mail: Lyan.ji@hznuzhuo.com

Whatsapp: 008618069835230

WeChat: 008618069835230

Nguva yekutumira: Kubvumbi-24-2025

Nhare: 0086-15531448603

Nhare: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com