Tekinoroji yekuparadzanisa mhepo inoyerera nemhepo inoyerera nemhepo ndeimwe yenzira dzakakosha dzekugadzira nitrogen neokisijeni yakachena zvakanyanya mumaindasitiri emazuva ano. Tekinoroji iyi inoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana akadai sesimbi, makemikari, uye mushonga. Chinyorwa chino chichaongorora zvakadzama kuti kupatsanurwa kwemhepo inoyerera nemhepo inoyerera nemhepo inoyerera nemhepo inoyerera nemhepo inoyerera nemhepo inoyerera zvakanyanya sei, pamwe nematanho akakosha nemidziyo inobatanidzwa mukuita uku.

1. Nheyo huru yekuparadzanisa mhepo ine cryogenic

Kupatsanurwa kwemhepo inoyerera (cryogenic air separation) inzira inoparadzanisa zvikamu zvikuru zvemhepo nekudzikisa tembiricha. Mhepo inonyanya kuumbwa nenitrogen, okisijeni, uye argon shoma. Nekudzvanya nekutonhodza mhepo kusvika patembiricha yakaderera zvikuru, mhepo inonyungudika, uye ipapo nzvimbo dzakasiyana dzekufashaira dzegasi rega rega dzinoshandiswa pakudiridza kuti nitrogen neokisijeni zviparadzanise. Nzvimbo yekufashaira yenitrogen i -195.8℃, uye yeokisijeni i -183℃, saka dzinogona kucheneswa zvakasiyana kuburikidza nekudiridza kwakatarwa.

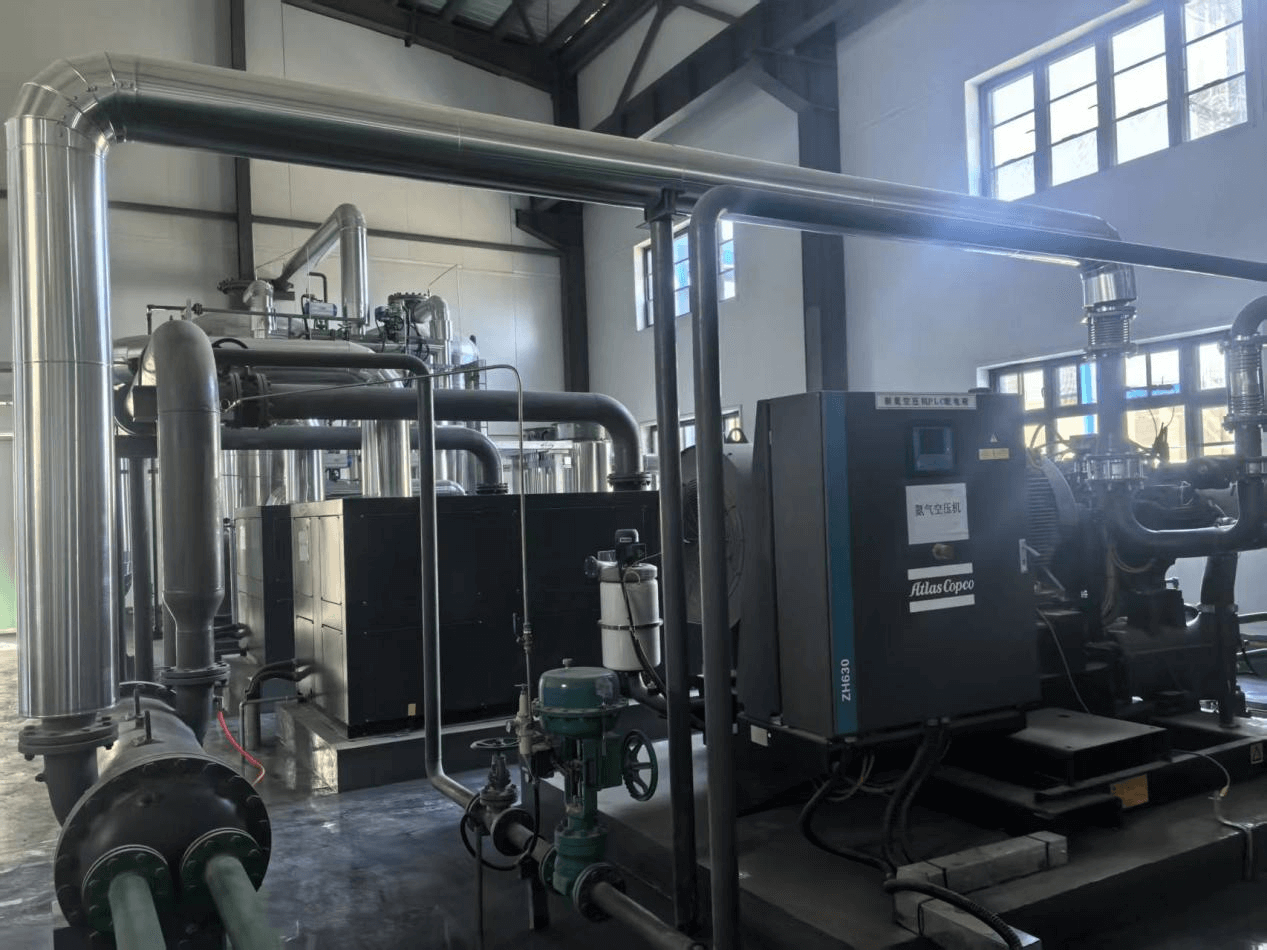

2. Danho rekutanga kurapwa: Kucheneswa kwemhepo

Munzira yekuparadzanisa mhepo ine cryogenic, kugadziriswa kwemhepo isati yatanga inhanho yekutanga inokosha. Mhepo ine tsvina yakaita seguruva, kabhoni diokisijeni, uye hunyoro, izvo zvinoomesa munzvimbo ine tembiricha yakaderera, zvichikonzera kuvharika kwemidziyo. Nokudaro, mhepo inotanga yaiswa mumatanho ekusefa, kudzvanywa, uye kuomeswa kuti ibvise tsvina nehunyoro. Kazhinji, madryer uye mamolecular sieve adsorbers zvishandiso zvakakosha zvinoshandiswa kubvisa tsvina kubva mumhepo, zvichivimbisa kugadzikana uye kushanda zvakanaka kwenzira inotevera yekuparadzanisa cryogenic.

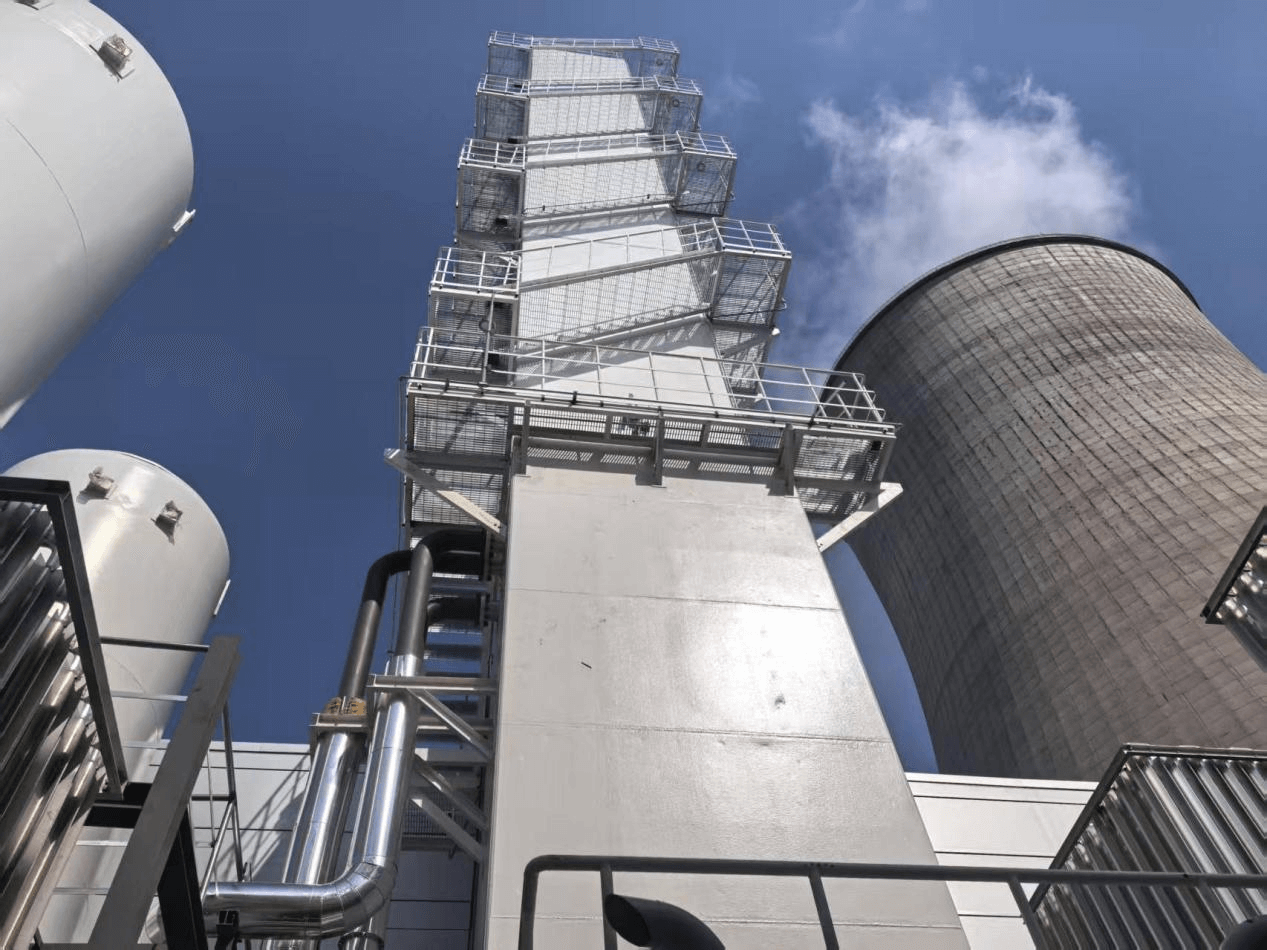

3. Kudzvanya uye kutonhora kwemhepo

Mhepo yakacheneswa inofanira kumanikidzwa, kazhinji kuburikidza nemacompressor akawanda kuti kumanikidzwa kwemhepo kuwedzere kusvika pamamegapascal mashanu kusvika matanhatu. Mhepo yakamanikidzwa inotonhodzwa kuburikidza nemaheat exchangers negasi rinodzoserwa patembiricha yakaderera, zvichideredza tembiricha zvishoma nezvishoma kuti isvike panzvimbo yekunyungudutsa. Mukuita uku, maheat exchangers anoita basa rakakosha, sezvo achigona kuderedza kushandiswa kwesimba zvinobudirira uye kuvandudza kushanda kwekutonhodza, achivimbisa kuti mhepo inogona kunyungudika mumamiriro ekunze ekupisa kwakaderera, zvichipa mamiriro ekupatsanurwa kwedhisiki kunotevera.

4. Kunyungudutsa kwemhepo uye kunyungudutsa

Mushongwe yekuparadzanisa ine cryogenic, mhepo yakamanikidzwa uye inotonhodzwa inotonhodzwa zvakare kusvika yanyorova. Mhepo yakanyorova inotumirwa kushongwe yekudiridza kuti iparadzaniswe. Shongwe yekudiridza yakakamurwa kuita zvikamu zviviri: shongwe ine kumanikidzwa kwakanyanya uye shongwe ine kumanikidzwa kwakaderera. Mushongwe ine kumanikidzwa kwakakwira, mhepo inoparadzaniswa kuita oxygen isina kuchena nenitrogen isina kuchena, uye ipapo oxygen isina kuchena nenitrogen isina kuchena zvinowedzerwa mushongwe ine kumanikidzwa kwakaderera kuti zviwane oxygen nenitrogen yakachena kwazvo. Kuparadzaniswa kwenitrogen neoxygen kunonyanya kushandisa hunhu hwavo hwakasiyana hwenzvimbo dzekufashaira, saka kuparadzaniswa kunoshanda kunogona kuwanikwa mushongwe yekudiridza.

5. Maitiro ekuchenesa

Okisijeni nenitrogen zvakaparadzaniswa mudura redhiraivha zvichiri netsvina shoma, saka zvinoda kucheneswa zvakanyanya kuti zvienderane nezvinodiwa zvemaindasitiri nezvekurapa. Kuchena kwenitrogen kunogona kuvandudzwa kuburikidza nehydrogen deoxygenation catalysts, nepo kuchena kweoxygen kuchigona kuwanikwa kuburikidza ne re-distillation processes. Kuti pave nekuchena kwegasi rechigadzirwa, michina yakaita se nitrogen purifiers ne oxygen purifiers inowanzo shandiswa, pakupedzisira zvichiwana zvigadzirwa zve oxygen ne nitrogen zvine hutsanana hwakawanda.

6. Mashandisirwo enitrogen neoxygen

Nitrogen yakachena uye okisijeni inogadzirwa netekinoroji yekuparadzanisa mhepo inonzi cryogenic inoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana. Nitrogen yakachena inoshandiswa muindasitiri yemakemikari segasi rinodzivirira uye rinotakura mweya, muindasitiri yechikafu chekuchengetedza nekurongedza, uye okisijeni inoshandiswa zvakanyanya mumaindasitiri ekurapa neanosanganisa simbi. Muindasitiri yesimbi, okisijeni inoshandiswawo kuvandudza kushanda zvakanaka kwemoto uye kuderedza kuburitswa kwekabhoni. Mukushandiswa uku, kuchena kwegasi ndiyo kiyi yekuona kushanda kwaro, uye tekinoroji yekuparadzanisa mhepo inonzi cryogenic yave kuzivikanwa zvakanyanya nekuda kwekuparadzanisa kwayo kwakanaka uye kubuda kwayo kwakachena.

7. Zvakanakira nematambudziko etekinoroji yekuparadzanisa mhepo ine cryogenic

Tekinoroji yekuparadzanisa mhepo inoputika inofarirwa muindasitiri nekuda kwekuchena kwayo kwakanyanya uye kushanda kwayo zvakanaka. Zvisinei, tekinoroji iyi inosanganawo nematambudziko, akadai sekushandisa simba rakawanda uye mari yakawanda yekugadzirisa michina. Kuti kuderedze kushandiswa kwesimba, michina yemazuva ano yekuparadzanisa mhepo inoputika inowanzouya nemasisitimu epamusoro ekuchengetedza simba, akadai semidziyo yekudzoreredza kupisa uye masisitimu ekutonhodza ematanho akawanda. Uyezve, kushandiswa kwetekinoroji yekudzora otomatiki kwakavandudza zvakanyanya kushanda zvakanaka uye kuchengetedzeka kwemayuniti ekuparadzanisa mhepo inoputika inoputika. Kuburikidza nekugadzirisa tekinoroji uye kuvandudzwa kwemidziyo, kushanda nesimba uye kugadzikana kwemasisitimu ekuparadzanisa mhepo inoputika inoputika zvakaramba zvichivandudzwa, zvichisimudzira kushandiswa kwavo mumaindasitiri akasiyana-siyana.

Kupatsanura mweya we "deep cryogenic" pari zvino ndiyo imwe yenzira dzinoshanda zvikuru dzekugadzira nitrogen neokisijeni yakachena kwazvo. Inopatsanura uye inochenesa okisijeni nenitrogen kubva mumhepo kuburikidza nematanho akasiyana-siyana akadai sekugadzirisa mhepo isati yatanga, kudzvanywa, kutonhodza, kunyungudutsa, uye kudirwa. Kunyangwe maitiro ekupatsanura mweya we "deep cryogenic" achishandisa simba rakawanda uye michina yakaoma, kupatsanura kwayo kunoshanda uye kuburitsa chigadzirwa chakachena kwazvo kunoita kuti tekinoroji iyi ive yakakosha mumaindasitiri akasiyana-siyana.

Anna Tel./Whatsapp/Wechat:+86-18758589723

Email :anna.chou@hznuzhuo.com

Nguva yekutumira: Chikunguru-14-2025

Nhare: 0086-15531448603

Nhare: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com